Our technologies are top notch in the metalworking industry.

High-output technology, fast turnaround times and superior quality are our priorities.

We are an industry leader in metal prototyping, custom fabrication, and production and

manufacturing of parts for most industries. Our large format, laser-precision cutting

technologies are capable of rapidly delivering large volumes at the highest quality levels.

NBG is well-equipped with large production and warehousing facilities in strategic

locations in Monterrey, Mexico and Texas, proudly serving these regional markets.

Punch Press

The AC-NT Series enables fabricators to greatly increase punching speeds—and combined with innovative

tooling designs—performs functions that would normally have to be done as secondary operations.

Some of these include: high-speed contouring, burr-free slotting, high-speed marking, and complex

forming that would normally have to be done by press brake. These expanded functions enhance productivity and reduce secondary operations.

Laser Inspection

Our Fabrivision electronic inspection technology of flat and 3D parts offers a

quick and accurate automated process. This technology was designed

specifically for the sheet metal industry, cuts inspections time to minutes,

and makes reverse engineering simple, improving overall efficiency. In addition,

the program can automatically collect inspection results for evaluation using

SPC (Statistical Process Control) methodology.

Press Brakes

This hybrid drive system incorporates AC servo motor driven bi-directional, high efficiency pumps providing high

speed ram movement and super accurate ram repeatability. This advanced design offers quick setup, high-speed

operation, and increased throughput. A CNC controlled hydraulic cylinders located in lower beam eliminate tool

shimming due to ram deflection. The super accurate, high speed 5-axis backgauge reduces positioning time and easily handles staging of complex parts.

Spot Welding

This Spot Welder provides an advanced technology solution to unpredictable, time consuming, and inefficient

spot welding by delivering consistently clean, spark-free welds across a wide range of flexible welding applications.

Its high frequency inverter power supply is the latest in welding technology. This vertical press type welding

machine combines the power of inverter technology with the accuracy. It also features a state-of-the-art welding unit,

designed for a high degree of control, efficiency, and safety.

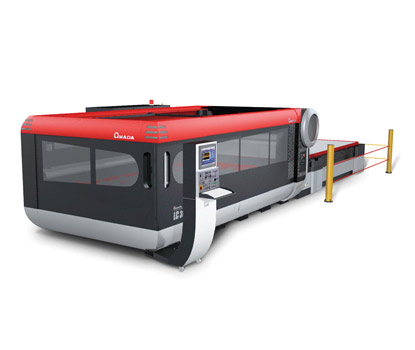

Laser Cutting

This laser cutting technology is engineered to provide high-speed processing, ultra-precise accuracy, superior cutting quality

and full-range capabilities. Featuring a 3-axis linear drive system, Amada’s

no lens change technology plus ultra-fast piercing and cutting takes productivity to a new level.

Additional features such as Cut Process Monitoring and an automatic nozzle changer set a new global standard for laser cutting systems.