quality is our source of pride

Precision that Powers Partnerships, Commitment that Drives Success

At NBG, quality is more than a checklist- it’s a mindset.

We don’t take shortcuts, and we don’t settle for “good enough.” Every part we produce is the result of a deliberate, disciplined process — one built on precision, consistency, and an uncompromising attention to detail. From the initial cut to the final inspection, quality isn’t just something we check for. See how that commitment comes to life in every finished part. We are compliant with AS9100 and ISO 9001 standards, with our certifications pending final approval.

The Promise Behind Every Part

The Equipment Behind the Excellence

We invest in inspection equipment that brings clarity and confidence to the shop floor. These tools help us measure faster, catch issues earlier, and ensure every part is within spec. Our Inspection Capabilities Include:

AMADA FabriVISION Laser Inspection System

High-resolution, non-contact camera inspection

Compares physical parts directly to CAD models

Identifies punching, laser cutting, and forming variations

Ideal for first-article inspection and reverse engineering

Supports rapid, reliable in-process checks

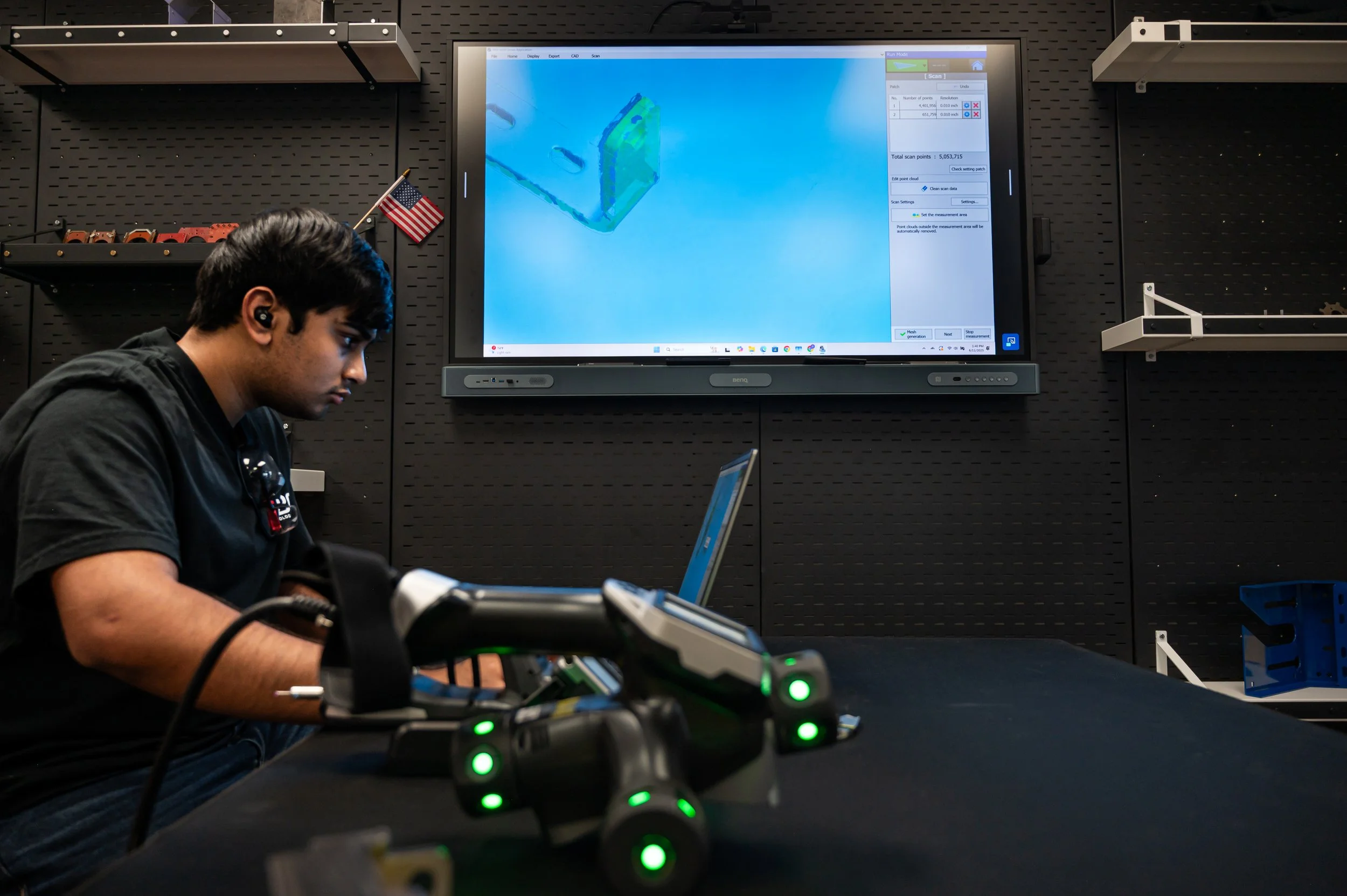

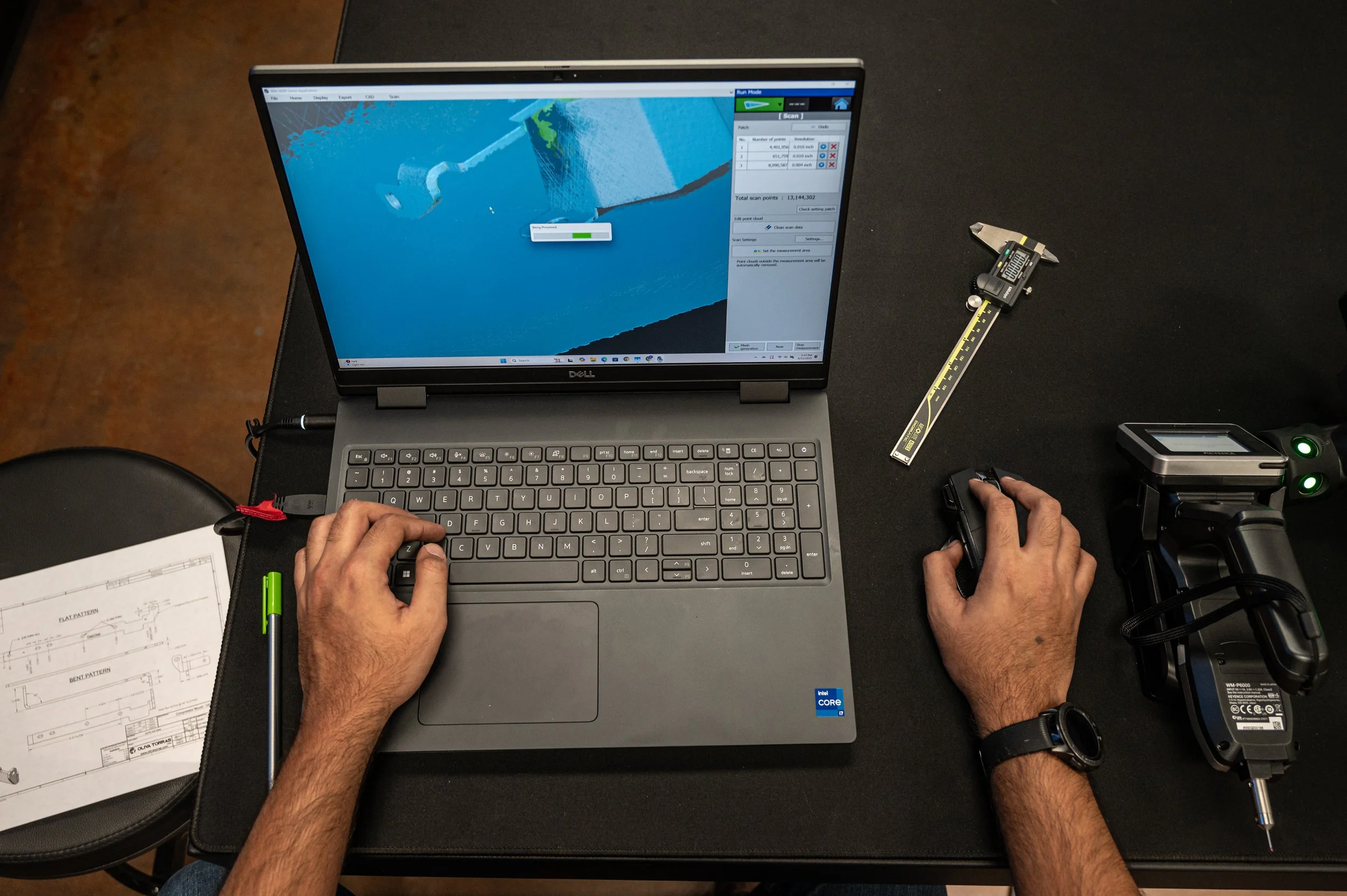

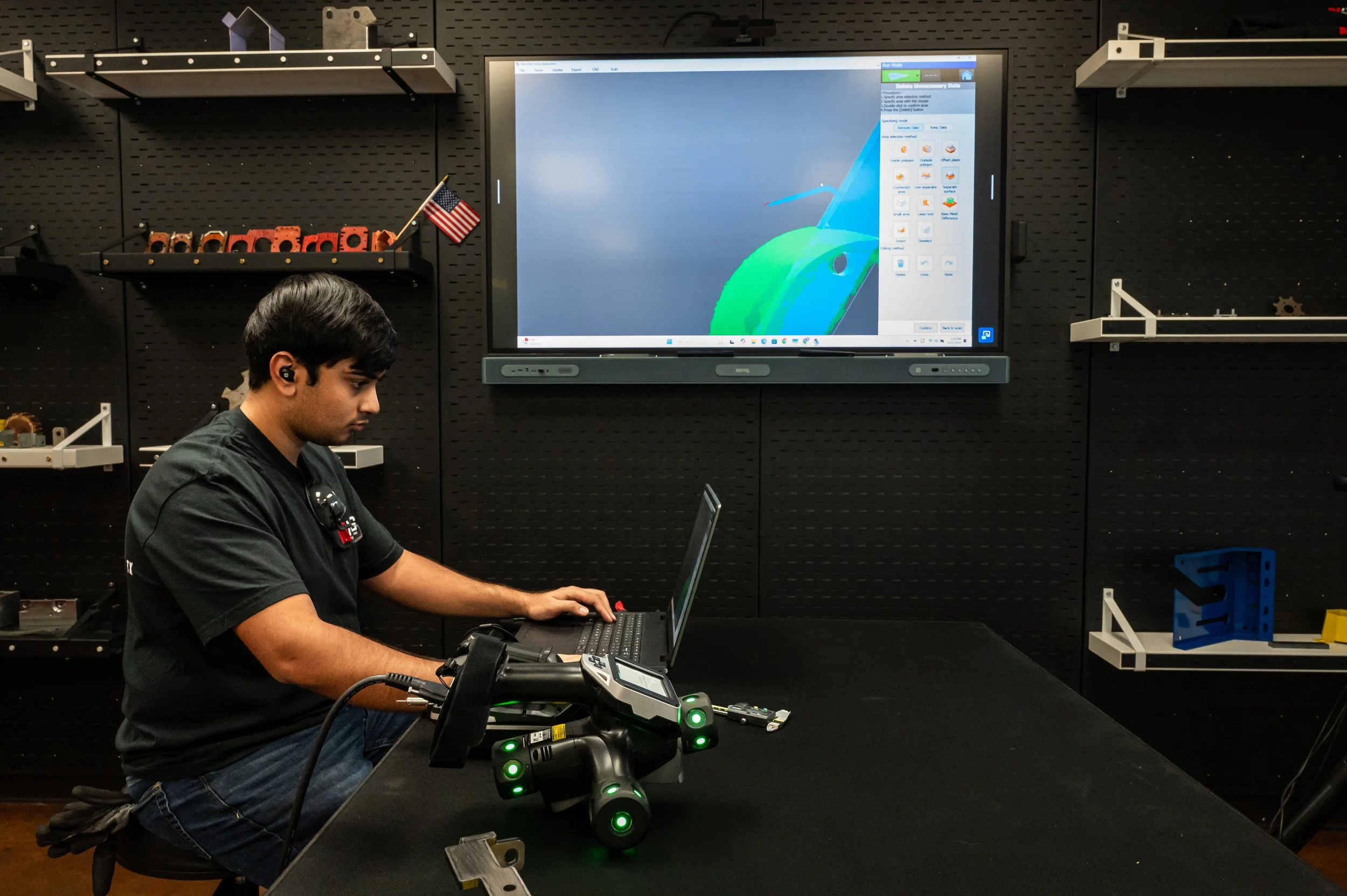

Keyence WM-6210 Wireless Spatial Measurement System

Portable 2D and 3D measurement system with CMM-level accuracy

Designed for large or geometrically complex parts

Captures precise GD&T data without custom fixturing

Improves speed and repeatability in inspection

Our Commitment to Quality in Action